Why wait?

The potential for operational excellence is within your reach. If you’re committed to achieving your strategic and tactical objectives efficiently and effectively, then it’s time to talk with Argo’s team of experts. Complete the form today, and a specialised team member will contact you to discuss how Argo can transform your business processes.

In 2021, we undertook a significant research and development project at Victoria University. We focused on the methods used by operational management professionals, and we meticulously identified their strengths and weaknesses. This comprehensive analysis led us to propose a new method to revolutionise how we address project management challenges.

Central to this method is the stipulation of building a model that accurately reflects the underlying business rules of the specific problem domain. In a nutshell, this method uses hard and soft constraints to suggest optimal solutions. Hard constraints represent the “must-have” requirements, ensuring all solutions adhere to them. In contrast, soft constraints are the “nice-to-have” attributes, and while every solution may not fully satisfy them, they serve as the foundation for optimisation. We conducted this study to provide tangible outcomes and validate the method’s application in real-world scenarios.

This research and development project culminated in creating a new operational optimisation method called “Operational Scheduling with Business Modelling and Genetic Algorithms. ”

Central to this method is the stipulation of building a model that accurately reflects the underlying business rules of the specific problem domain. In a nutshell, this method uses hard and soft constraints to suggest optimal solutions. Hard constraints represent the “must-have” requirements, ensuring all solutions adhere to them. In contrast, soft constraints are the “nice-to-have” attributes, and while every solution may not fully satisfy them, they serve as the foundation for optimisation. We conducted this study to provide tangible outcomes and validate the method’s application in real-world scenarios.

This research and development project culminated in creating a new operational optimisation method called “Operational Scheduling with Business Modelling and Genetic Algorithms. ”

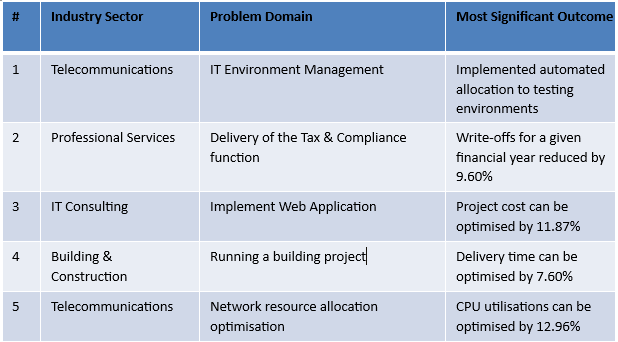

We applied the Argo AI—OMO method in several case studies, and the optimisation delivered efficiency gains of between 8% and 20% of the total operational costs. The table below demonstrates these outcomes.